![]()

Environmental protection without borders

![]()

Environmental protection without borders

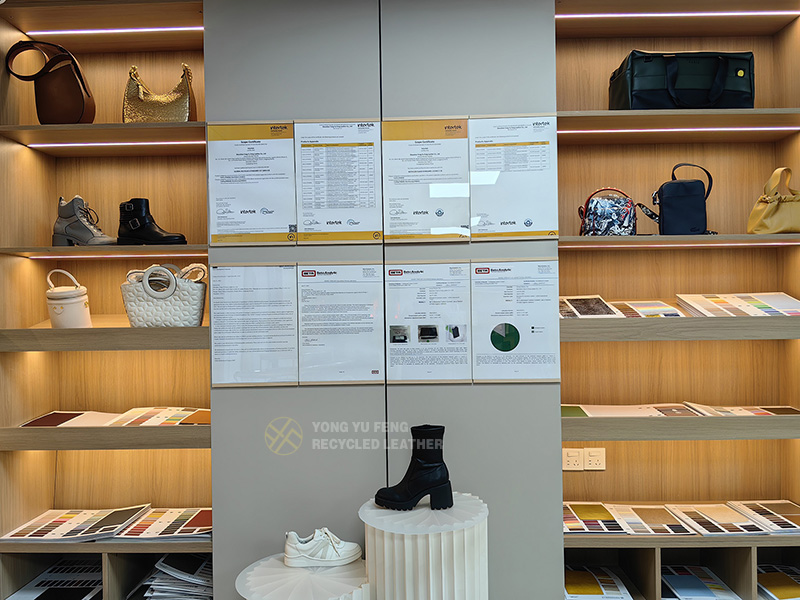

All environmentally friendly leather products under Shenzhen Yongyufeng Leather can pass OEKO-TEX ® STANDARD 100 international ecological textile certification, becoming one of the few leather manufacturing enterprises in China to obtain this “confidence textile” label. This certification marks that Yongyufeng products have met the world’s most stringent standards in over 300 hazardous chemical substance tests, including zero detection of banned azo dyes, heavy metals, organotin compounds and other hazardous substances, providing international luxury brands with leather substrates that combine luxury texture and health and safety protection.

Innovative Technology: The Hard Core Strength Behind Environmentally Friendly Leather

Yongyufeng has been deeply involved in the research and development of environmentally friendly leather for 19 years. This certified product embodies three core innovations:

Recycled water-based environmentally friendly leather technology: using water-based polyurethane coating instead of traditional solvent based materials, reducing VOC emissions by more than 70% during the production process, while leading the industry in wear resistance and flexibility indicators;

Marine plastic recycling process: converting recycled plastic bottles and fishing net waste into high-quality recycled leather fabrics, achieving resource recycling, and reducing carbon emissions by about 1.8 tons per ton of product;

Biobased Degradable Materials: By integrating 100% plant fibers with biobased polymers, a naturally degradable leather series has been developed. It won a spot in the top four of the Green Environmental Protection Award at the 2025 Shanghai International Luxury Packaging Exhibition.

Through independent research and development of six layers of clean technology, Yongyufeng has successfully integrated wear-resistant, scratch resistant, waterproof, anti fouling, and antibacterial functions, extending the lifespan of leather by more than 30%. Its testing center simulates extreme usage scenarios – repeatedly wiping with gradient alcohol solution for thousands of times to verify durability, providing luxury brands with a “lossless” quality guarantee.